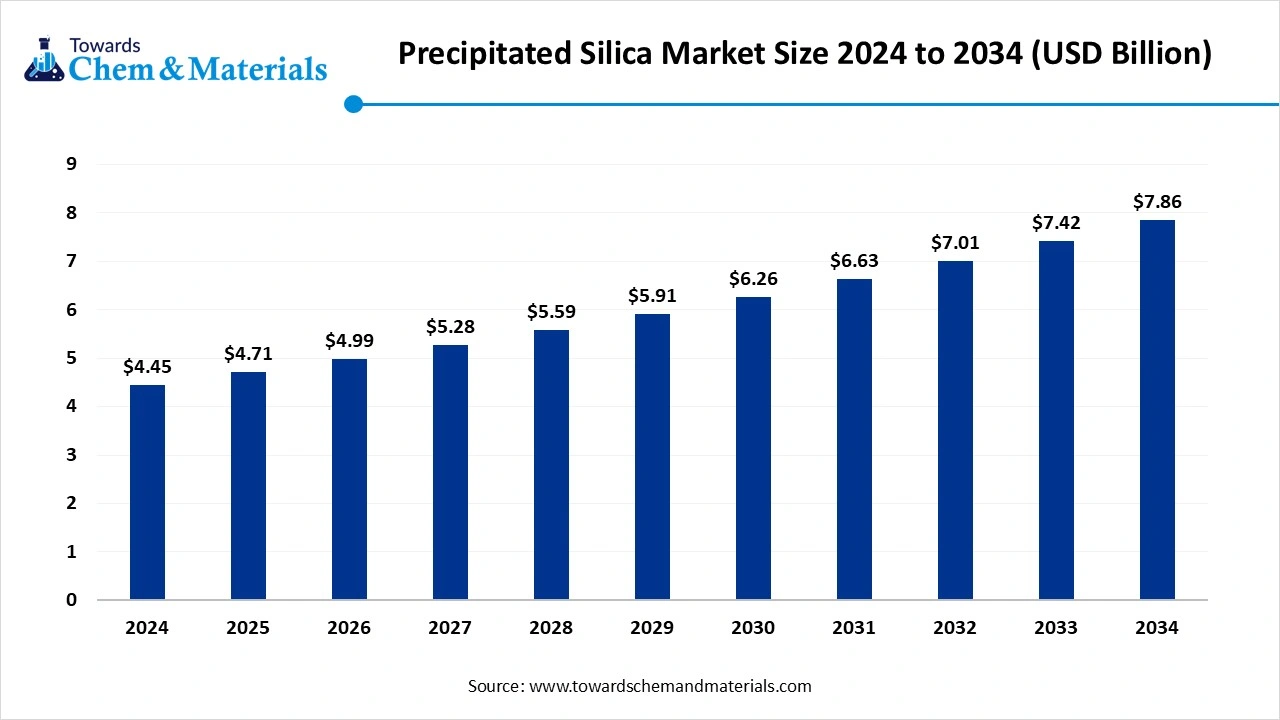

Precipitated Silica Market Size to Worth USD 7.86 Bn by 2034

According to Towards Chemical and Materials Consulting, the global precipitated silica market size was accounted for USD 4.71billion in 2025 and is expected to be worth around 7.86 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.85% from 2025 to 2034.

Ottawa, Dec. 01, 2025 (GLOBE NEWSWIRE) -- The global precipitated silica market size was valued at USD 4.45 billion in 2025 and is predicted to increase from USD 4. 49 billion in 2026 is anticipated to reach around USD 7.86 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.8 % over the forecast period 2025 to 2034. Rising demand from the automotive and tire industry for high performance fillers is a key growth factor driving the participated market. A study published by Towards Chemical and Materials a sister firm of Precedence Research.

Download a Sample Report Here@ https://www.towardschemandmaterials.com/insights/precipitated-silica-market

What is Precipitated Silica?

The precipitated silica industry is expanding strongly, driven by rising demand in the tyre and rubber industry, where silica improves performance and fuel efficiency. Production is becoming more advanced, focusing on engineered surface properties and eco-friendly methods. While industrial-grade silica still dominates, high-purity grades are growing in areas like oral care and pharma. The Asia Pacific region stands out as a major hub, supported by large automotive and chemical manufacturing capacity.

Precipitated Silica is manufactured by the company using the latest Spray Drying Technology to provide the finished product in Fine Powder, Micro Pearl as well as Granulations form. It is a pure white synthetic amorphous material, which is inert, non-toxic, chemically balanced and suited for diverse applications. The product undergoes further processing like Granulations, Milling, etc. to cater to different applications.

Precipitated Silica manufactured at GMGBC meets international quality standards and offered for sale to Tyre / Rubber, Dental / Toothpaste, Pesticides, Food / Feed, Plastics / Ink / Detergents, Latex Products and several other segments. Highly acclaimed for imparting superior properties suited for various applications, GMGBC Precipitated Silica is stable even after long storage under recommended storage conditions and safe packaging adopted by the company.

GMGBC has also successfully developed High Dispersion Silica using advanced technology for improved dispersion in Rubber Compounds and superior Rubber Compound properties. This grade finds application in Eco-friendly Green Tyres for lower Rolling Resistance, better Road Grip and lower Heat Build Up.

Request Research Report Built Around Your Goals: sales@towardschemandmaterials.com

Precipitated Silica Market Report Highlights

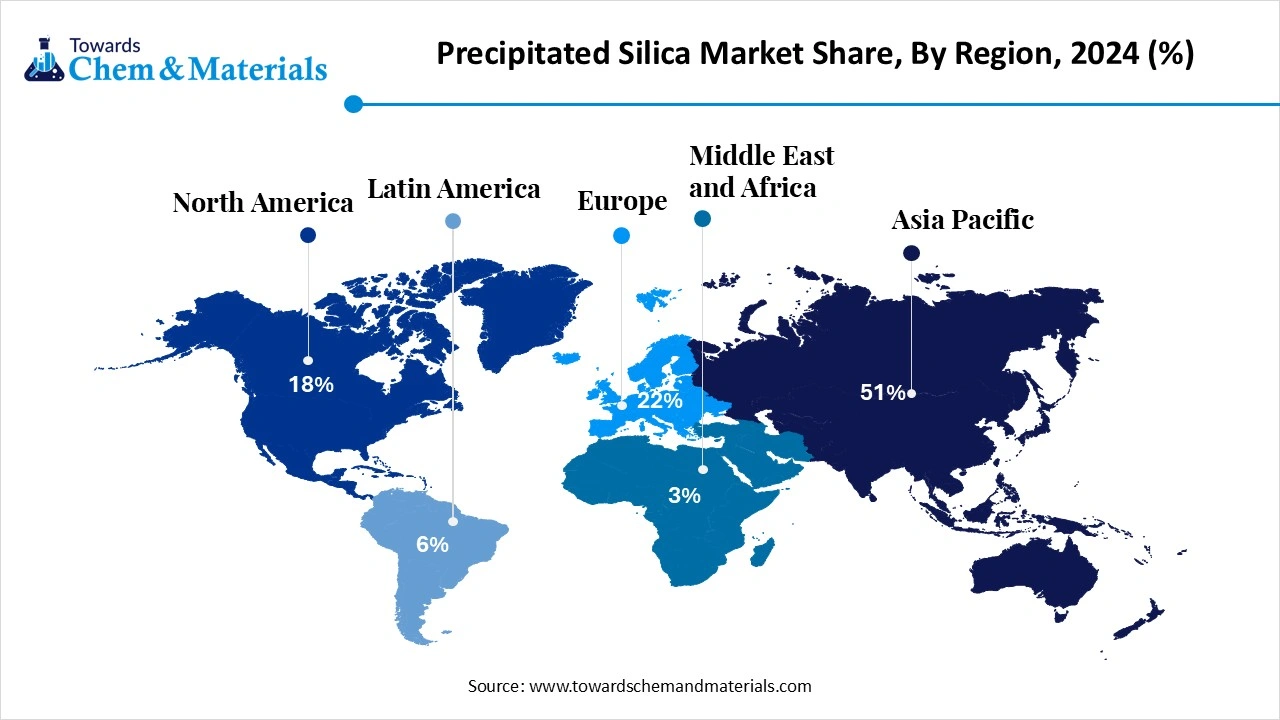

- The Asia Pacific precipitated silica market held the largest share of 51% of the global market in 2024.

- By application type, the tires segment held the largest market share of 63% in 2024.

- By product type, the highly dispersible silica segment held the largest market share of 52% in 2024.

- By form, the micropearl/granular segment held the largest market share of 58% in 2024.

- By function, the reinforcing filler segment held the largest market share of 61% in 2024.

- By purity type, the industrial grade segment held the largest market share of 78% in 2024.

- By end customer, the tire OEMs & tire rubber compounders segment held the largest market share of 59% in 2024.

Major Private Industry Investments in the Precipitated Silica Industry:

- Evonik Acquisition of Huber Silica: In 2016, Evonik acquired J.M. Huber's silica business for $630 million, a major move to expand its global market position, particularly in dental applications.

- Qemetica Acquisition of PPG Silica Business: Qemetica acquired PPG's entire precipitated silica products business for approximately $310 million in late 2024, significantly boosting its presence in the North American and European markets.

- Evonik Charleston Plant Expansion: Evonik invested a significant amount to expand the capacity of its Charleston, South Carolina, plant by 50% to meet the increasing North American demand for precipitated silica in "green" tires.

- Tata Chemicals Capacity Expansion: The company's board approved a major investment of around $93 million (Rs 775 crore) to expand its precipitated silica manufacturing capacity in Cuddalore, Tamil Nadu, to cater to the growing automotive and rubber industries.

- Solvay Changshu Plant Expansion: Solvay significantly bolstered its position in the Asia-Pacific market by doubling the production output at its Changshu site in China.

- Evonik "Smart Effects" Merger: Evonik strategically merged its Silica and Silanes business lines into a new entity called "Smart Effects" in early 2025 to offer more integrated, innovative solutions for demanding applications like EV batteries and semiconductors.

- PQ Corporation Acquisition of Sibelco Business: In January 2025, PQ Corporation completed the acquisition of Sibelco Group's specialty silicate business in Sweden, expanding its Nordic region presence.

- AksharChem India Capacity Expansion: AksharChem India expanded its precipitated silica capacity by 50% to 18,000 TPA to meet rising demand and strengthen its position in the Indian market.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5924

Precipitated Silica Market Report Scope

| Report Attribute | Details |

| Market size value in 2026 | USD 2.29 billion |

| Revenue forecast in 2034 | USD 7.86 Billion |

| Growth Rate | CAGR of 5.85% from 2025 to 2034 |

| Base year for estimation | 2025 |

| Historical data | 2020 - 2025 |

| Forecast period | 2025 - 2034 |

| Quantitative Units | Volume in kilotons, revenue in USD million, and CAGR from 2025 to 2035 |

| Report coverage | Volume forecast, revenue forecast, competitive landscape, growth factors, and trends |

| Segments covered | By Application, By Product Type, By Form, By Function, By Purity / Compliance Grade, By End Customer, By Region |

| Regional scope | North America; Europe; Asia Pacific; Central & South Africa; Middle East & Africa |

| Country scope | U.S.; Canada; U.K.; Germany; Spain; France; Italy; China; India; Japan; Brazil; Saudi Arabia; United Arab Emirates; South Africa |

| Key companies profiled | Anten Chemical Co. Ltd.; Huber Engineered Materials; Evonik Industries AG; PPG Industries , Inc.; IQE Group; Solvay S.A.; PQ Corporation; MLA Group; Tosoh Silica Corporation; Oriental Silicas Corporation; W.R. Grace & Co.; Madhu Silica Pvt. Ltd. |

For more information, visit the Towards Chemical and Materials website or email the team at sales@towardschemandmaterials.com| +1 804 441 9344

How Is Precipitated Silica Used?

The relatively large size and high total surface area of precipitated silica particles lend themselves to providing good liquid adsorptive capacity, made possible by a large network of interconnected pores within each particle. This ability to adsorb water can help prevent the clumping of solid particles in powdered products if exposed to water. Precipitated silica’s relatively large particle size is also useful for creating an abrasive effect within formulations to provide polishing or cleaning of various surfaces. Also, precipitated silica particles also have silanol groups available to interact with other particles, albeit not to the same degree as fumed silica. Thus, precipitated silica can be used to thicken liquid formulations.

Precipitated Silica Applications

- Boosting Oral Care Cleaning: Precipitated silica provides polishing and cleaning and induces thickening in oral care products, such as toothpaste.

- Enhancing Food and Pharmaceutical Consistency: Adding precipitated silica prevents caking and clumping in powdered food products and pharmaceutical formulations.

- Providing Material Reinforcement: Incorporation of precipitated silica into materials such as rubber can provide reinforcement and strengthening.

- Modifying Film Appearance: Precipitated silica reduces gloss and provides a matte effect to coatings, paints, and inks.

What Are the Major Trends in the Precipitated Silica Market?

- There is a growing shift toward sustainable production, with manufacturers minimising energy and water use to reduce environmental impact.

- Increasing integration of engineered surface chemistry is enhancing silica’s performance for specialised applications.

- Ready-to-handle forms are gaining adoption because they improve handling safety and consistency.

- Demand is diversifying into higher purity grades, especially for food, pharma, and oral care applications.

How Does AI Influence the Growth of the Precipitated Silica Industry in 2025?

AI is expected to strongly influence the precipitated silica industry in 2025 by optimising production through predictive maintenance models and real-time analytics, which reduce downtime and improve efficiency. Machine learning algorithms help detect equipment anomalies before they lead to failure, boosting operational reliability in silica plants. AI-driven simulations also support process design, enabling manufacturers to fine-tune reaction parameters, improve consistency, and lower consumption. These advances not only improve cost structure but also enhance the sustainability of silica production.

Market Opportunity

Could Green Silica from Rice Husk Ash Power a Sustainable Circular Economy?

Using high-rusk ash to make precipitated silica turns abundant agricultural waste into a high-value, low-carbon material.

Might Silica Nano power redefine Eco-Friendly Beauty and Pharma?

Bio-silica derived from agricultural residues offers a renewable, high-purity alternative for applications in cosmetics and pharmaceuticals.

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5924

Precipitated Silica Market Segmentation Insights

Application Type Insights:

Why the Tires Segment Dominated the Precipitated Silica Market?

The tires application dominated the market because it is widely used as a reinforcing filler in the rubber compounds that make up modern tyres. This application benefits from the industry’s drive to improve rolling resistance, wet-grip performance, and fuel economy, causing tyre manufacturers to increasingly adopt silica to replace part of the carbon black in their formulations.

Product Insights:

Why did the Highly Dispersible Silica Segment Dominate the Precipitated Silica Market?

The highly dispersible silica product type dominates the market in the market because it offers superior mix ability and consistent batch performances, making it especially attractive for tyre and high-performance rubber applications that demand uniform dispersion and reliable reinforcement.

Form Insights:

Which Form Dominates the Precipitated Silica Market?

The micropearl/granular form dominated the market in 2024 because its dust-free nature and excellent flow behaviour make it safer and more efficient to handle. This physical form reduces inhalation risks for workers, improves dosing accuracy in manufacturing equipment, and minimises losses during packaging and transport. As a result, manufacturers favour granules in large-scale production setups, where consistent batch quality and process efficiency are top priorities.

Function Insights:

Which Function Segment Lead the Precipitated Silica Market in 2024?

The reinforcing filler function led the market, because silica used in this way greatly enhances the mechanical attributes of elastomers and plastics. By improving tensile strength, tear resistance, and abrasion life, silica under this function helps make high-performance rubber products, especially for tyres, more durable and reliable.

The matting/ antiblock function is expected to expand most rapidly, driven by increasing demand from the packaging and film industries. These applications increasingly rely on which are becoming more important as consumer packaging aesthetics and functionality continue to evolve.

Purity Insights:

Why the Industrial Grade Purity Segment Dominated the Precipitated Silica Market?

The industrial-grade purity type dominates the market because it offers a cost-effective balance of performance and scale. It is well-suited for large volume, cost-sensitive applications such as rubber goods, construction materials and general technical goods where ultra-high purity is not required but robustness and volume are essential.

The food/ pharma grade purity type is projected to grow the fastest, driven by stricter regulatory standards, higher demand for traceability, and increased use of silica in oral-care, pharmaceutical, and nutraceutical products. Manufacturers are increasingly turning to certified, high-purity silica to meet the quality and safety needs of these sensitive applications.

Regional Insights

How Does Asia Pacific Dominate the Precipitated Silica Market?

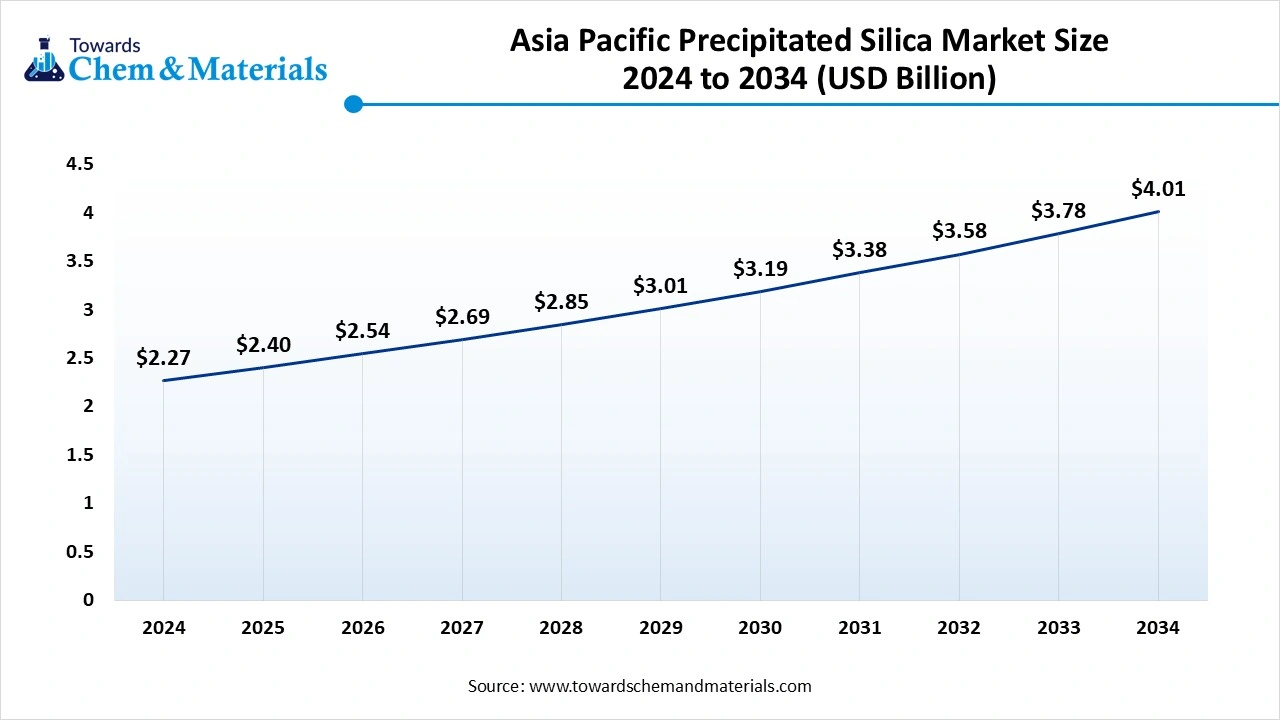

The Asia Pacific precipitated silica market market size was valued at USD 2.27 billion in 2024 and is expected to surpass around USD 4.01 billion by 2034, expanding at a compound annual growth rate (CAGR) of 5.86% over the forecast period from 2025 to 2034.

The Asia Pacific region dominated the market largely because of its massive automotive and tyre manufacturing infrastructure, which makes silica a key reinforcing filler. Heavy chemical production capacity across countries like China, India, and Japan further supports large-scale silica production, while abundant ant raw materials and strong downstream demand help sustain growth.

China Precipitated Silica Market Trends

China plays a central role in the market due to its vast rubber goods manufacturing sector, especially for tyres, which drives high domestic consumption. Local manufacturers are increasing capacity to cater to growing silica demand, while also tailoring silica grades to meet regional performance needs, such as heat and wear resistance in rubber.

How Is Europe Expected to Soar in The Precipitated Silica Industry?

Europe is projected to grow at a strong pace in the market, driven by increasing demand for high-performance and speciality applications. Regulatory pressure toward more sustainable materials is pushing manufacturers to invest in greener production methods. The rise of green tyre technology and other eco-friendly silica uses is helping push adoption across the region. Established chemical infrastructure and a strong push for innovation are making Europe a key battleground for silica suppliers.

Germany Precipitated Silica Market Trends

Germany stands out as a major market within Europe due to its robust automotive industry, which demands advanced silica for performance tyres and high-durability compounds. Local chemical companies are heavily investing in silica technologies and sustainable production to align with both industrial performance needs and environmental regulations. The country’s engineering excellence and capacity to customise silica grades give it a competitive edge. Its central role in Europe’s chemical supply chains makes it a strategic hub for particulate silica development.

More Insights in Towards Chemical and Materials:

- Silica Market : The global silica market size was reached at USD 40.85 billion in 2024 and is expected to be worth around USD 98.05 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.15% over the forecast period 2025 to 2034.

- Polyaniline Market : The global polyaniline market size is calculated at USD 1.84 billion in 2025 and is predicted to increase from USD 1.95 billion in 2026 and is projected to reach around USD 3.22 billion by 2035, The market is expanding at a CAGR of 5.75% between 2026 and 2035.

- Silica Market : The global silica market volume is estimated at 559.03 million tons in 2025, and is expected to reach 954.14 million tons by 2034, at a CAGR of 6.12% during the forecast period 2025-2034.

- Silica For S-SBR Market : The global silica for s-sbr market size is calculated at USD 2.57 billion in 2024, grew to USD 4.50 billion in 2025, and is projected to reach around USD 4.50 billion by 2034. The market is expanding at a CAGR of 5.75% between 2025 and 2034.

- Polyglycerol Market : The global polyglycerol market size is calculated at USD 7.96 billion in 2025 and is predicted to increase from USD 8.82 billion in 2026 and is projected to reach around USD 22.30 billion by 2035, The market is expanding at a CAGR of 10.85% between 2026 and 2035.

- Steel Market : The global steel market size is calculated at USD 1.69 trillion in 2025 and is predicted to increase from USD 1.77 trillion in 2026 and is projected to reach around USD 2.66 trillion by 2035, The market is expanding at a CAGR of 4.65% between 2026 and 2035.

- Polyurethane Market : The global polyurethane market size is calculated at USD 89.97 billion in 2025 and is predicted to increase from USD 94.84 billion in 2026 and is projected to reach around USD 152.38 billion by 2035, The market is expanding at a CAGR of 5.41% between 2026 and 2035.

Precipitated Silica Market Top Key Companies:

- Oriental Silicas Corporation (OSC)

- Madhu Silica

- Tokuyama

- Qingdao Makall Group

- Shandong Link Silica

- PPG

- W. R. Grace

- Tosoh

- Shandong Hongda

- Quemax (Zhejiang)

- Brazil

Precipitated Silica Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2019 to 2034. For this study, Towards Chemical and Materials has segmented the global Precipitated Silica Market

By Application

- Tires

- Non-Tire Rubber

- Oral Care

- Food & Feed (Anti-caking)

- Coatings, Inks, Adhesives & Plastics

By Product Type

- Highly Dispersible Silica (HDS)

- Conventional Precipitated Silica (CPS)

- Oral Care & Food/Pharma Grades

- Specialty Functional (Matting/Anti-block/Carrier)

By Form

- Micropearl / Granular

- Powder

By Function

- Reinforcing Filler

- Abrasive / Rheology Modifier

- Anti-caking / Free-flow

- Matting / Anti-block

By Purity / Compliance Grade

- Industrial Grade

- Food / Pharma Grade

By End Customer

- Tire OEMs & Tier Rubber Compounders

- Oral Care Formulators

- Food & Feed Producers

- Film/Coatings/Plastics Converters

By Regional

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.towardschemandmaterials.com/checkout/5924

About Us

Towards Chemical and Materials is a leading global consulting firm specializing in providing comprehensive and strategic research solutions across the chemical and materials industries. With a highly skilled and experienced consultant team, we offer a wide range of services designed to empower businesses with valuable insights and actionable recommendations.

Our Trusted Data Partners

Towards chem and Material | Precedence Research | Statifacts | Towards Packaging | Towards Healthcare | Towards Food and Beverages | Towards Automotive | Towards Consumer Goods | Nova One Advisor | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us: https://www.linkedin.com/company/towards-chem-and-materials/

USA: +1 804 441 9344

APAC: +61 485 981 310 or +91 87933 22019

Europe: +44 7383 092 044

Email: sales@towardschemandmaterials.com

Web: https://www.towardschemandmaterials.com/